Arc Flash Label Requirements: Your Complete Guide to NFPA 70E Compliance

An overview of arc flash labeling considerations and workplace electrical safety

Important Disclaimer

This article is provided for general informational purposes only and does not constitute legal, safety, or professional compliance advice. Regulations, standards, and codes are subject to change and may be interpreted differently by authorities having jurisdiction (AHJ). Always consult with qualified safety professionals, licensed engineers, or legal counsel to determine the specific requirements applicable to your facility. TagBuilder is not responsible for any actions taken based on this information.

An arc flash event releases temperatures up to 35,000°F—four times hotter than the surface of the sun. The blast pressure can throw workers across rooms, molten metal can ignite clothing, and the intense light can cause permanent blindness. Yet the equipment that harbors these risks often sits in plain sight, sometimes unlabeled or inadequately identified.

The Regulatory Framework: NFPA 70E and OSHA

Arc flash labeling requirements primarily come from NFPA 70E, Standard for Electrical Safety in the Workplace. While NFPA 70E itself isn't a law, OSHA references it as the recognized industry consensus standard, and OSHA's General Duty Clause (Section 5(a)(1)) requires employers to provide a workplace free from recognized hazards—including electrical hazards.

Key Standards Interconnection

- NFPA 70 (NEC) 110.16: Requires arc flash warning labels on equipment during installation

- NFPA 70E Article 130: Establishes labeling requirements for workplace safety and specifies label content

- IEEE 1584: Provides the calculation methods for determining incident energy and arc flash boundaries

What NFPA 70E Requires: Article 130.5(H)

NFPA 70E 2024 Edition, Article 130.5(H) establishes the labeling requirements for electrical equipment. Labels must include at least one of the following sets of information:

Option 1 - Incident Energy Analysis Information: - Nominal system voltage - Arc flash boundary - Available incident energy and corresponding working distance - Date of the arc flash hazard analysis

Option 2 - Table-Based PPE Category: - Nominal system voltage - Arc flash boundary - Arc flash PPE category (per Table 130.5(G)) - Date the label was applied

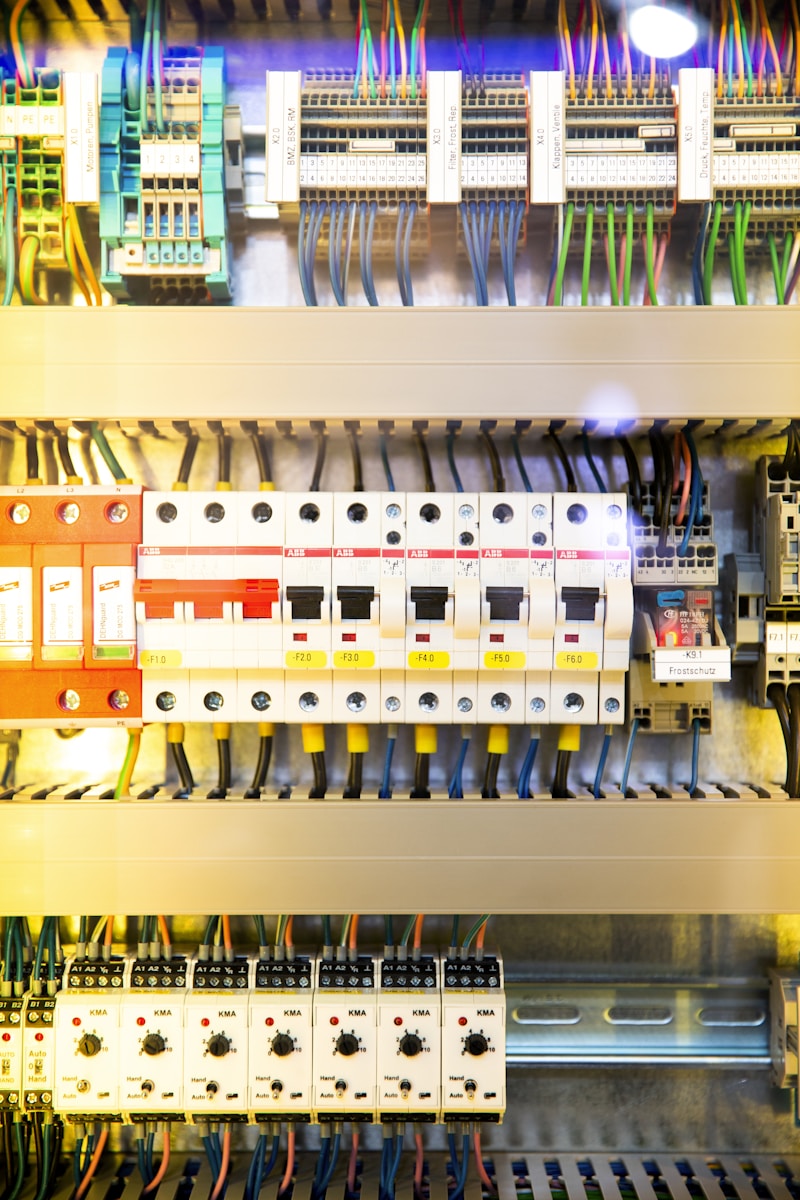

Critical Equipment Requiring Labels

Labels are required on equipment "likely to require examination, adjustment, servicing, or maintenance while energized." This includes switchboards, switchgear, panelboards, industrial control panels, motor control centers, and meter socket enclosures.

Understanding the Label Content Requirements

Arc Flash PPE Category

NFPA 70E Table 130.5(G) establishes four PPE categories:

| Category | Minimum Arc Rating | Typical Equipment |

|---|---|---|

| 1 | 4 cal/cm² | Low-energy panelboards, small MCCs |

| 2 | 8 cal/cm² | Medium-energy switchboards, larger panels |

| 3 | 25 cal/cm² | Higher-energy switchgear, large MCCs |

| 4 | 40 cal/cm² | Maximum PPE category |

Important: If incident energy exceeds 40 cal/cm², the task cannot be performed energized.

Arc Flash Hazard Analysis Date

Labels must show the date of the analysis. The arc flash risk assessment shall be reviewed for accuracy at intervals not to exceed 5 years, and whenever a major modification or renovation takes place.

The Evolution of Arc Flash Labeling Requirements

Pre-2002: No Specific Requirements

Before NFPA 70E's arc flash provisions and NEC 110.16, there were no specific arc flash labeling requirements.

2002-2012: Basic Warning Labels

The NEC 110.16 initially required only a generic warning label: "Arc Flash Hazard. Appropriate PPE Required."

2018-Present: Current Requirements

Current NFPA 70E editions require comprehensive information detailed above. Labels must provide workers with specific, actionable information—not just general warnings.

Label Design and Construction Requirements

Durability Considerations

Labels must remain legible for the life of the installation or until the next scheduled reassessment. Environmental factors affecting label selection include temperature exposure, UV exposure, oil, grease, and chemical exposure, and cleaning requirements.

Recommended materials: - Thermal transfer printed polyester for moderate environments - Laminated vinyl for chemical resistance - Engraved phenolic or aluminum for harsh environments and permanent installations

Label Placement

Labels must be visible to qualified persons before examination, adjustment, servicing, or maintenance. They should be located on or adjacent to the equipment and positioned so they can be read without opening doors or removing covers.

Common Compliance Failures

Based on inspection findings and industry experience, these are frequent arc flash labeling deficiencies:

- Outdated Labels: Labels that haven't been updated after system modifications or that exceed the 5-year review interval

- Missing Equipment: Failure to label all equipment requiring examination while energized

- Incomplete Information: Labels missing required elements

- Generic Warning Labels: Old-style labels without quantitative hazard information

- Illegible Labels: Labels that have degraded due to environmental exposure

- Labels Inside Enclosures: Labels placed where workers must open the equipment to read them

Conclusion: Labels as Safety Communication

Arc flash labels represent the communication link between your engineering analysis and the worker standing in front of energized equipment. A well-designed, properly installed, accurately maintained label provides that worker with essential information:

Here's the voltage. Here's how dangerous this could be. Here's how far back you should stand. Here's the protection you need.

Investing in quality arc flash labels, keeping them current, and ensuring workers understand them isn't just about NFPA 70E compliance. It's about ensuring that every person who approaches your electrical equipment has the information they need to go home safely.

Need Arc Flash Labels for Your Facility?

Keeping your arc flash labels current and compliant protects your workers and keeps you on the right side of NFPA 70E. TagBuilder produces durable arc flash labels engineered to remain legible in demanding electrical environments.

Our custom label builder lets you create:

- Labels with all required NFPA 70E information fields

- Custom incident energy values from your arc flash study

- Durable materials that withstand heat and UV exposure

- Professional formatting that meets industry standards

Design your arc flash labels now →

Have arc flash study results you need turned into labels? Contact us for bulk pricing on custom arc flash labels.